Horizontal lifelines are usually installed on concrete walls or steel structures at height of about

1.2m.The lifeline arrangement at this height is more convenient for use, and there are no particular

requirementsfor the lifeline installation and slider mechanism. The slider can pass through the intermediate

brackets smoothly, traversing a whole lifeline over hundred meters. If the slider is stuck occasionally at

certain positions, manual intervention is quite easy.

For some special locations, such as where the gap between the workshop crane and the workshop

pillars is very small, the lifeline cannot be installed at the conventional positions. Instead, it can only

be installed at an overhead position to avoid the interference with the workshop crane, and the slider

has to be attached on the lifeline in form of upside-down. In addition, a steel wire rope is needed to let

the user connect himself with the slider, which results in the pressure of the slider on the lifeline much

higher than that in conventional situations. In such condition, the lifeline is pulled downward, and

furthermore the slider may not pass through the intermediate brackets smoothly or even be stuck on

them during slider traversing. In case slider stagnation occurs, manual intervention is nearly impossible.

Therefore, the overhead-installed horizontal lifeline has very high requirements for the slider mechanism

and the intermediate brackets.

For this special situation, ASAT developed an overhead-installed horizontal lifeline 'SAFLY HE+SHLB-01D',

which can be installed 4m or even higher overhead above the ground. The slider adopts four-wheel

two-column structure, and the rolling wheel guide groove adopts a special section, which has better

guiding performance and fault tolerance. Variable anchor point design makes slider traversing more

smoothly; The steel limit plate in cooperated with double rope lifeline completely eliminates the

possibility of slider stripping off.

ASAT has conducted a comprehensive test to the overhead-installed horizontal lifeline.

The static strength of the slider is tested by static tensile tester. Static tensile value is set to

15kN, which is higher than that of 12kN required by European standard, and the hold time is

3min. Test result shows that no visible deformation is found on the slider; The static strength

of the slider on lateral direction is also tested. Static tensile value is set to 12kN and the hold

time is 3min. The test result shows that no break is found on the slider.

The horizontal lifeline in the length of 11.35m is installed overhead, 4.1m above the ground,

and the smooth and dynamic tests are conducted.

Smoothness test: Several persons, connecting themselves to the lifeline, walk in different speeds

and speed variations along the lifeline to different locations in the application zone. The test result

shows that the slider moves smoothly along the lifeline all the time and no manual intervention is

required.

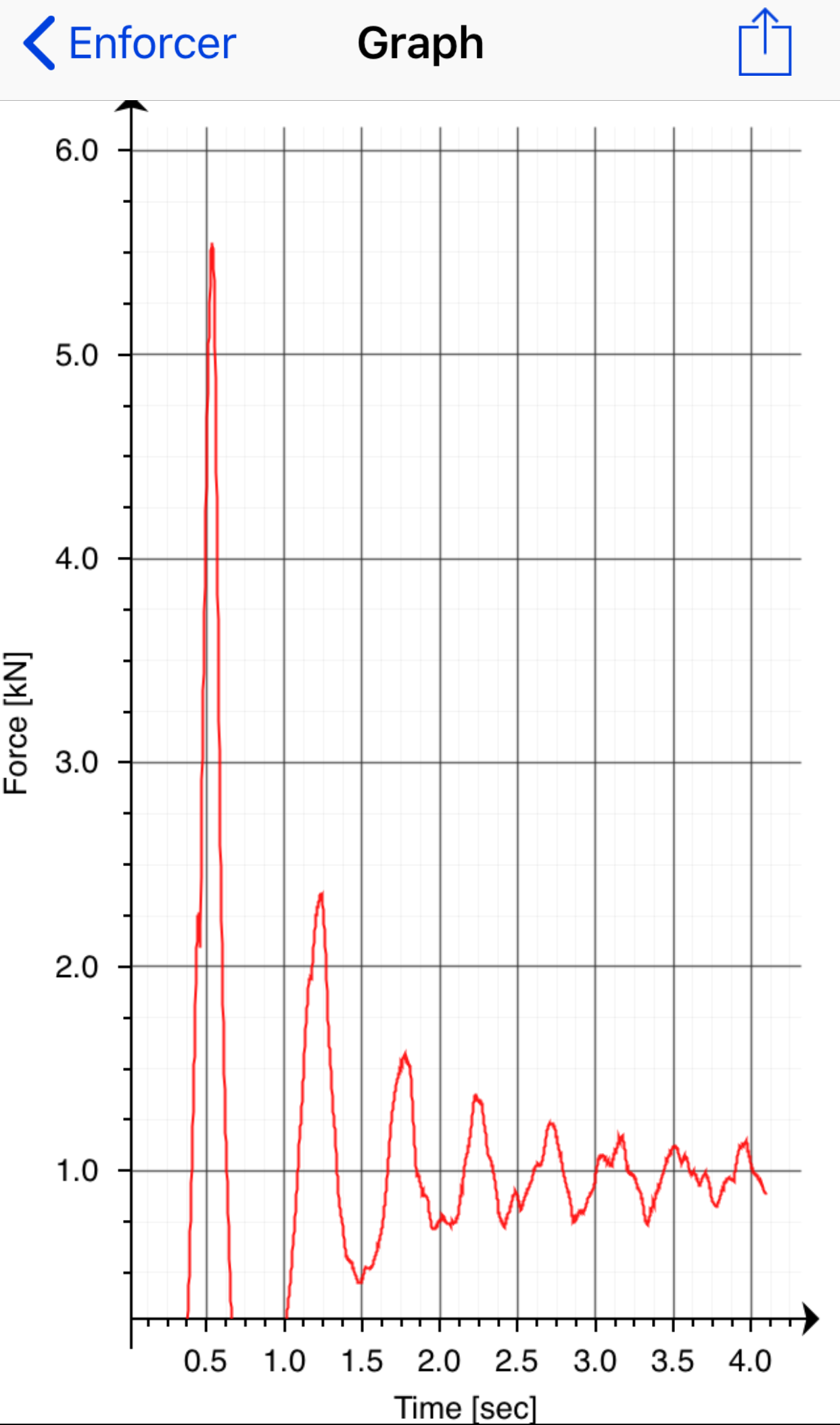

Dynamic test: a test weight of 100kg and a dynamic rope in length of 1m is used to conduct the

dynamic test.

Fall factor is equal to 1. The test result shows that the impact load is less than 6kN;

Simulate the condition of two persons falling one after another. Test results shows that the maximum

impact load on the second person during the falling is 5.5kN.