1. The purpose

ASAT power ascender is for personnel ascent and descent. To be on the safe side, all the rope used with ASAT power ascender must be passed the rope compatibility test.

2. Precautions for choosing the rope:

2.1 Not all EN 1891 type A ropes are compatible with ASAT power ascender.

2.2 After many tests, ASAT suggests: the rope which is densely braided used with ASAT power ascender, the radial deformation of the rope is relatively smaller and there’ll be more friction between the rope and the sheave under the same load compared with soft rope. The soft rope may cause slippage in the sheave, and even squeeze between the sheave and pulley, then lead to damage of the rope and the device.

2.3 The results obtained by this testing method are also influenced by the following factors: rope condition, wear degree of the sheave and cover, and environmental conditions - air humidity.

3. Test preparation:

3.1. Rope:

3.1.1 Considering the practicality of rope access and the objectivity of testing, ASAT does not recommend pre-treatment of ropes, such as soaking and drying, to maintain their original state.

3.1.2 Rope diameter: 11 ± 0.2mm.

3.1.3 Rope length: 7 ± 0.5m. (the height of anchor 6m, rope length should be longer than the height of anchor 1m)

3.1.4 The upper end of the rope should be a figure-8 knot or a sewn termination.

3.1.5 For one rope model, you should have 2 samples to do the test.

3.2 Test equipment

3.2.1 It is necessary to use an ASAT power ascender which is in good condition to do the test (especially for the rope sheave and cover are in good condition).

3.2.2 The height of the anchor should be at least 6m.

3.2.3 The breaking load of anchor shall be at least 12kN.

3.2.4 The components used for testing should comply with the requirements of PPE standards.

3.3 Testers

3.3.1 They’re proficient in operating the power ascender.

3.3.2 Maintain a safe distance of 5m from the vertical line of the load or have a protective shelter.

3.4 Test environment requirements: Environmental conditions, especially for air humidity, have a direct impact on the test results.

3.4.1 Temperature: 15-25 ℃.

3.4.2 Relative humidity: 45% -55%.

4. Test:

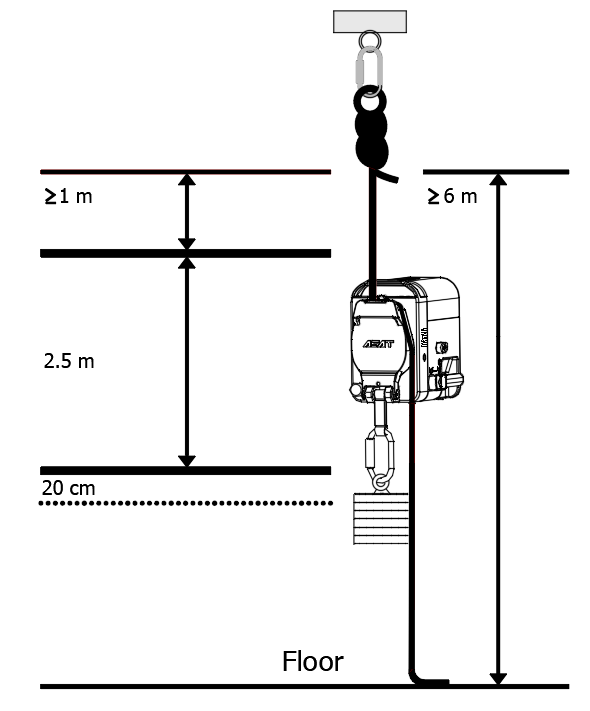

4.1 Rope installation and marking: as shown in the following figure

4.1.1 The rope should be installed on the anchor that comply with EN 795 at a height of 6m or on an anchor with similar static strength. If the anchor position is higher than 6m, a steel wire rope can be used to extend the anchor to ensure a height of 6m. Tie a figure-8 knot or use the sewn termination of rope to connect the anchor.

4.1.2 Connect the 7m rope to the anchor as a test rope.

4.1.3 Use a marker to mark the upper and lower ends of the 2.5m zone, with the lower end indicates the start point of ascent and stop point of descent, and the upper end indicates the stop point of ascent and start point of descent.

4.1.4 Use a marker to make a tolerance mark 20cm below the lower end to measure the slippage distance during descent.

4.1.5 Make sure the rope is installed correctly, and the rope should have a margin of about 1m for the rope installation in the power ascender.

4.2 Test: Each rope sample should undergo the following five tests in order. If any one of them does not meet the requirements, it cannot pass the test. The tested rope samples should not be serious damaged on rope sheath (i.e. you can directly see the core of rope), and the tested rope should also meet the manufacturer's inspection requirements.

4.2.1 Test 1: Rope installation and uninstallation test

4.2.1.1 Procedure: Select three different sections of the unloaded rope. Install them in the power ascender and then remove the rope according to the instruction of device.

4.2.1.2 Result: If the installation and uninstallation of rope are functioning well, the rope sample will pass this test.

4.2.2 Test 2: Moving test:

4.2.2.1 Procedure:

Using a load that is 1.25 times heavier than the rated load of the power ascender.

Install the rope in the power ascender.

Operate the device with the remote control to slowly lift the load to the upper mark of rope (you can pull the free end of rope to avoid slippage between the rope and the sheave).

Use the remote control to quickly descend the load and stop at the lower mark of rope.

4.2.2.2 Result:

The ascent is functioning well, and after the emergency stop of descent, if the slippage length is no more than 20cm, the rope sample will pass this test.

4.2.3 Test 3: Static load test.

4.2.3.1 Procedure:

Make a mark on the free side of rope near the pulley of the power ascender that completed Test 2.

Slowly increase the load on the device to 1.5 times the rated load and maintaining for 3 minutes;

4.2.3.2 Result:

Check the position of rope mark, if there is no significant rope slippage, the rope sample will pass this test.

4.2.4 Test 4: Performance test

4.2.4.1 Procedure:

Use a specified load (150kg for ACE-24 and 120kg for ACE-22) on the power ascender.

Use the remote control to control the device to the lower mark of rope.

Use the remote control to control the device with the specified load to ascend and descend between the upper and lower mark of the rope for a total of 50 circles.

4.2.4.2 Result:

If the power ascender is functioning well during the test, and there is no damage on the rope after the test,the rope sample will pass this test.

4.2.5 Test 5: Rope installation and uninstallation test

4.2.5.1 Procedure:

Select the severely worn parts of the ropes that have completed test 4, and take three different sections of rope for installation and uninstallation test in the power ascender.

4.2.5.2 Result:

If the installation and uninstallation of rope are functioning well, the rope sample will pass this test.